SKU #10528

Čepele do univerzálních nožů (ostré)

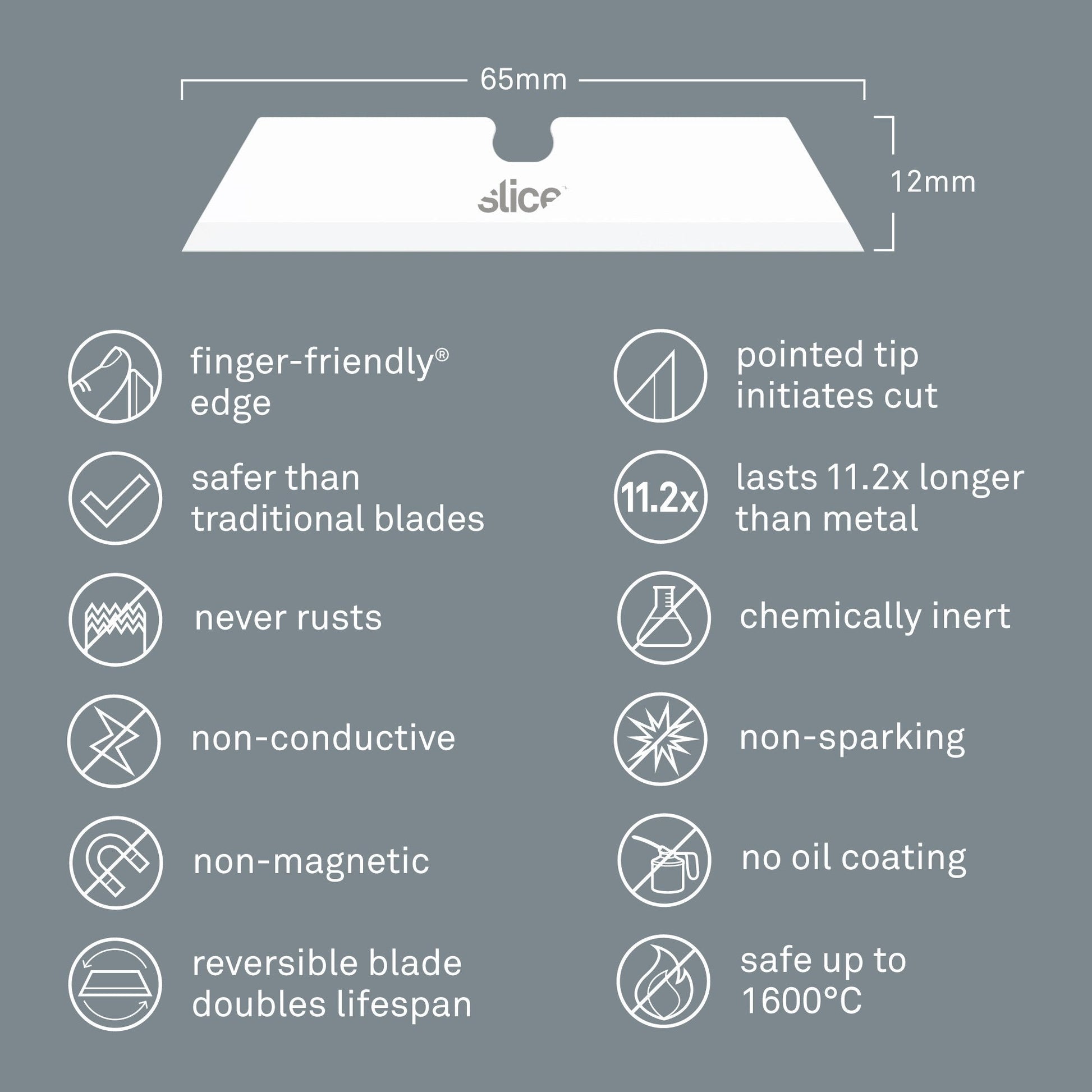

Čepele Slice® 10528 do univerzálních nožů mají ostrou špičku, díky níž můžete řezaný materiál nejprve propíchnout. Stejně jako všechny bezpečnostní čepele Slice jsou i čepele 10528 nejiskřivé, nemagnetické a chemicky netečné; nepodléhají korozi a nepotřebují žádné mazání. Naše unikátní finger-friendly® ostří je bezpečné na dotyk, takže minimalizuje zranění při práci a snižuje vaše náklady. Tyto čepele jsou kompatibilní s rukojeťmi několika nástrojů Slice: univerzálních nožů 10550, 10554, 10558 a 10562, špachtlí 10591 a 10593 a polohovatelného nože na kartony 10585.

- Druh čepele: ostrá

- Bezpečnější než tradiční čepele

- Efektivní finger-friendly® ostří

- Vydrží až 11,2krát déle než kovové čepele

- Méně výměn čepele = méně zranění

- Méně zranění, nižší náklady

- Nejiskřivé, nevodivé, nemagnetické

- Chemicky netečné, nepodléhající korozi

- Čepele nevyžadují mazání

- Ostrá špička snadno propíchne řezané materiály

- 100% recyklovatelné

- Čepele vydrží při teplotách od -40°C do 1600°C

- Kompatibilní rukojeti: 10477, 10479, 10550, 10554, 10558, 10562, 10563, 10564, 10585, 10591, 10593

- Jedno balení obsahuje 3 oboustranné čepele

- SKU #10528

Product Specifications

Product Specifications

Cutting Depth:

Material: zirconium oxide

Dimensions: L x W x H

Weight: 0.026 kg

Kompatibilní produkty

Videa

-

Cut Roof Membrane Safely With Slice

-

How to Cut Pallet Wrap and Banding

-

How to Cut Ceiling Tile: Safety First

-

How to Cut Corrugated Plastic Sheets Using Slice Tools

-

How to Cut Drywall Safely With Slice

-

How To Cut Mylar Stencils

-

Cutting Ram Board®

-

How to Cut Super Sacks® Easily and Safely

-

How To Cut Window Screen Using Slice Tools

-

The Correct Technique to Cut Plastic Banding

-

Blade Replacement for the Folding Utility Knife

-

Replacing Carton Cutter Blades

-

Blade Replacement on Slice Utility Scrapers

-

Blade Replacement for Slice Utility Knives

Související produkty

Časté dotazy

Are Slice Ceramic Utility Knife Blades Safer?

Compared with standard blades (that’s steel or traditional ceramic), the answer is yes. When you search “how to change a utility knife blade”, you learn that the process is often dangerous. Overly sharp blades leave your hands vulnerable to injury.

Because we developed a proprietary finger-friendly edge for our ceramics, handling a Slice ceramic blade is less dangerous than handling a traditional ceramic or steel utility knife blade. Our manufacturing process creates an edge that effectively cuts material but is safe to the touch.

Slice utility knife replacement blades are made from hard zirconium oxide. That, along with our manufacturing process, is why our blades hold their edge, on average, 11.2 times longer than steel. This means you’ll be handling your blade much less often, which also reduces the chance of injuries.

Because we developed a proprietary finger-friendly edge for our ceramics, handling a Slice ceramic blade is less dangerous than handling a traditional ceramic or steel utility knife blade. Our manufacturing process creates an edge that effectively cuts material but is safe to the touch.

Slice utility knife replacement blades are made from hard zirconium oxide. That, along with our manufacturing process, is why our blades hold their edge, on average, 11.2 times longer than steel. This means you’ll be handling your blade much less often, which also reduces the chance of injuries.

Which Type of Utility Knife Blade Should I Use for the Job?

The best utility knife blades will depend on your application. For most cuts, our 10526 (rounded tip) blades will do the job. The rounded tip provides an added layer of safety against accidental puncture wounds. For some materials, though, a pointed tip is required. A pointed tip initiates a clean cut with a piercing action and is best used for materials like shrink wrap, laminating sheets and plastic banding.